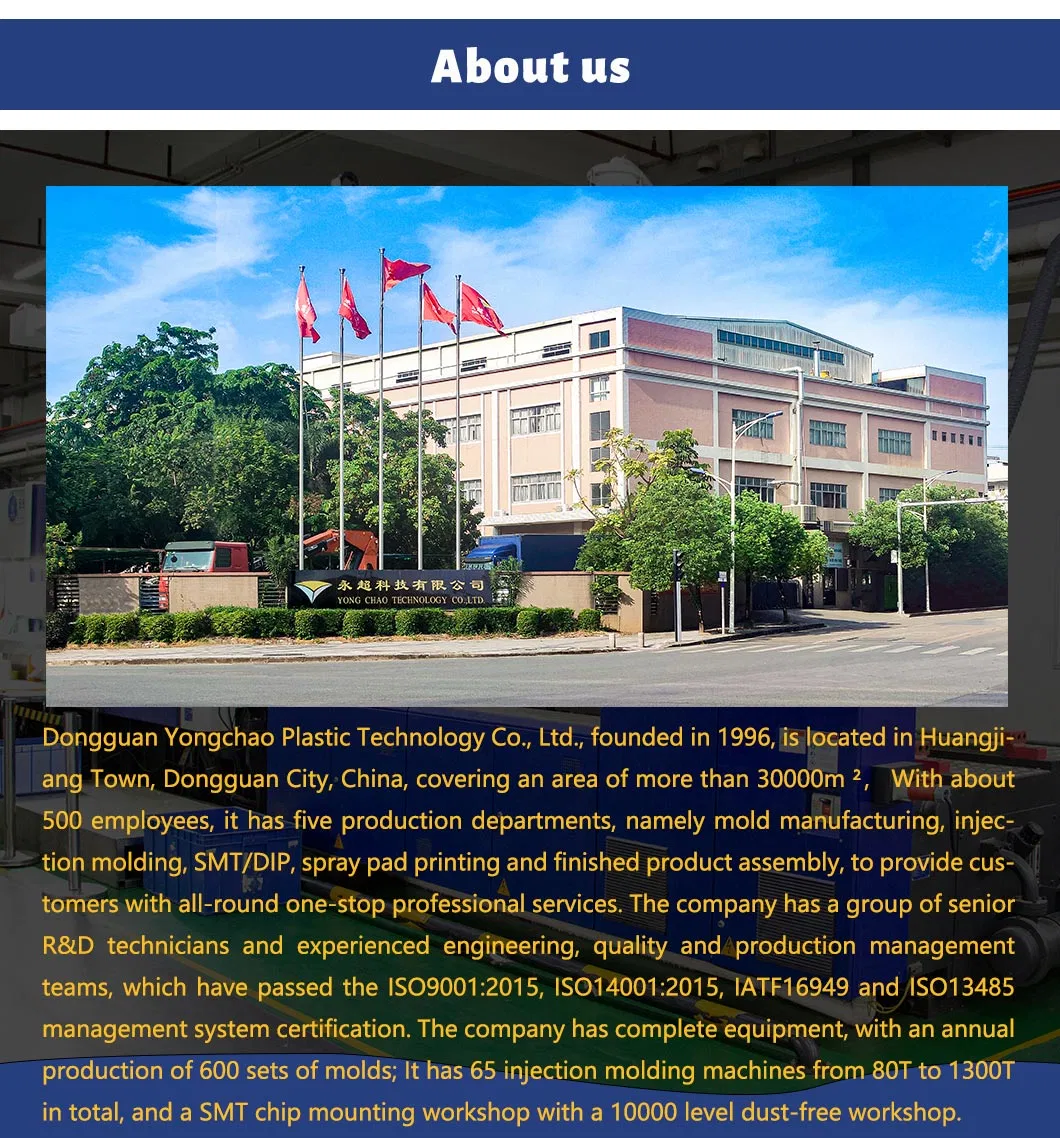

Audi and Ford Chinese Automobile Plastic Part Supplier

Basic Info.

| Model NO. | YC-0008 |

| Outer Plate Type | Cold Plate |

| Seal Material | Thermoplastic Elastomer Seal |

| Open Type | Forward |

| Hinge Connecting Method | Welded Joint |

| Glass Lift Type | Wire Drive |

| Outer Plate Thickness | 0.85mm |

| Door Check Limited Power Providing Method | Rubber Spring Type |

| Door Check Friction Force Type | Rolling Friction Type |

| Processing Technique | Split Type |

| Transport Package | Standard Export Package |

| Origin | Made in China |

| Production Capacity | 600 Dies of Year |

Packaging & Delivery

Package Size 22.00cm * 32.00cm * 43.00cm Package Gross Weight 30.000kgProduct Description

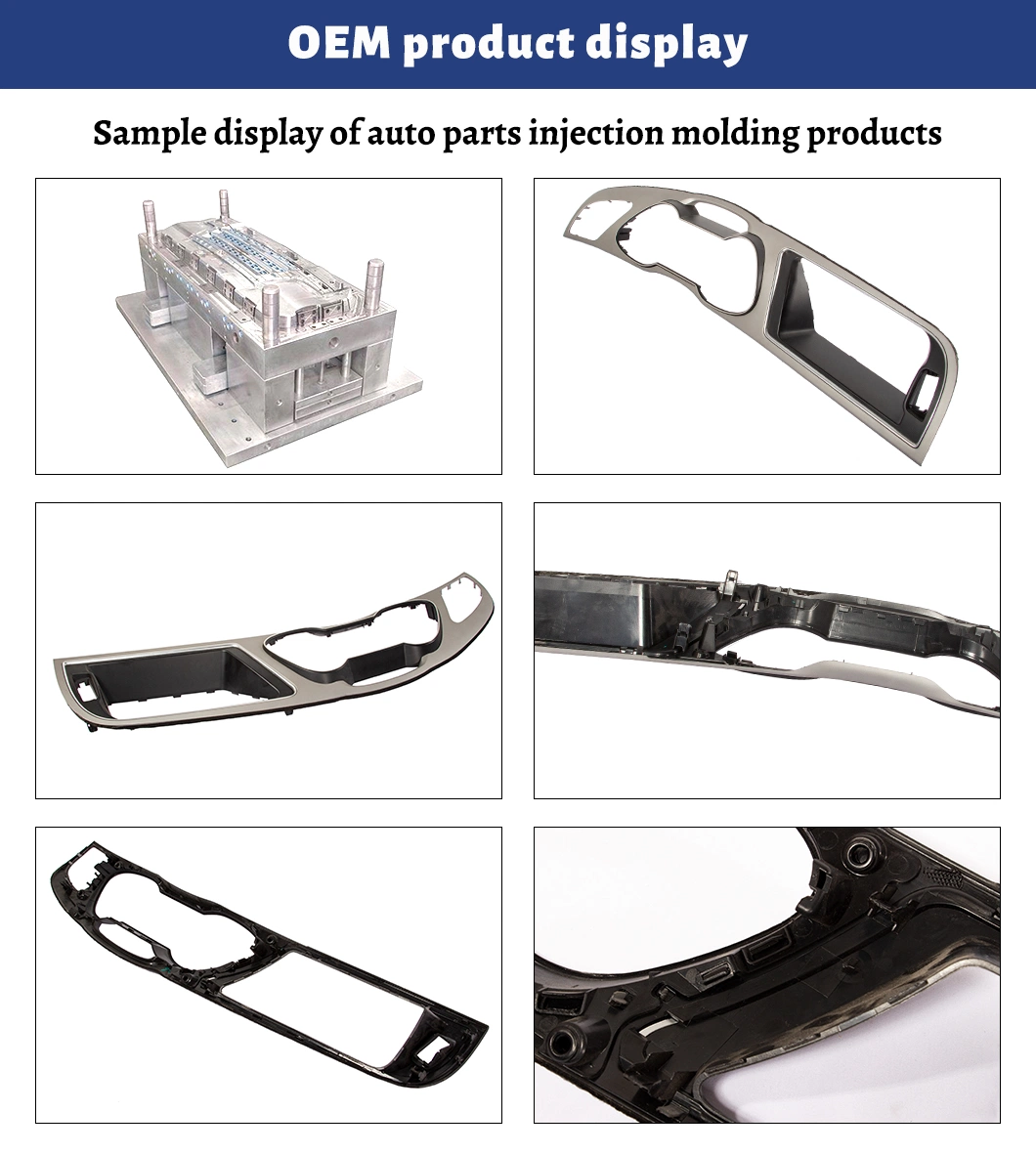

Audi and Ford Chinese automobile plastic part supplierWhat is injection molding?

Injection molding is a method of producing parts by injecting material into a mold. Metals (for which the process is known as die-casting), glasses, elastomers, confections, and, most commonly, thermoplastic and thermosetting polymers can all be used in injection molding. The part's material is fed into a heated barrel, mixed, and forced into a mold cavity, where it cools and hardens to the cavity's configuration. After a product is designed, usually by an industrial designer or engineer, molds are made from metal, usually steel or aluminum, and precision-machined to form the desired part's features. 3D printing materials like photopolymers which do not melt during the injection molding of some lower temperature thermoplastics can be used for some simple injection molds. Injection molding is widely used for producing a wide range of parts, from very small to very large. The ability to produce parts with varying geometrical shapes and sizes is determined by the type of machine used in the operation.

| Product Name | battery case power station shell | Product material | ABS,PP, Nylon,PC or any other material as you need | ||||||||||||||

| Place of Origin | Guangdong,China | Tonnage | 80-1300T | ||||||||||||||

| Type of enterprise | Professional manufacturer of injection molds andplastic parts | Production ability | 10,000pcs/day | ||||||||||||||

| Service | ODM,OEM,Design based on your idea or Make mold and produce based on your drawing | Package | Standard carton, pallet or customized | ||||||||||||||

| Size | As Custom's Requst | Prototype | 3D printing, CNC, Laser cutting etc. | ||||||||||||||

| Shipping way | By Courier DHL, Fedex, TNT, UPS, EMS, By Sea, By Air | Drawing format | Step., igs., x_t, dwg, pdf, stl(for 3D print)etc. | ||||||||||||||

| Assembly & Test | Five production department | Design software | Solidworks, Pro-E, UG, CAD, Rhino etc. | ||||||||||||||

| Payment details | T/T, L/C, D/A, D/P, Western Union, MoneyGram, Veem, Paypal etc | surface | As Custom's Requst,heat treatment.polishing, texture,coating,etc | ||||||||||||||