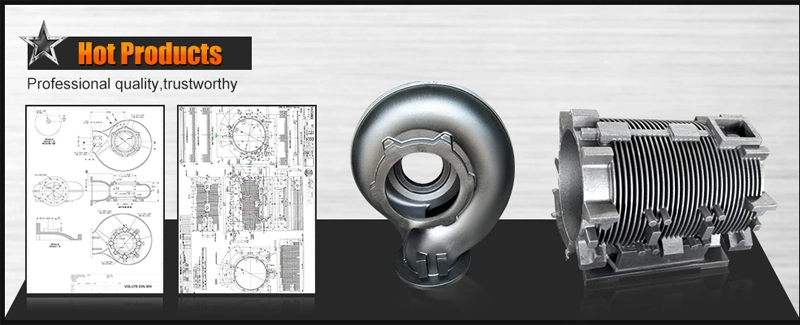

OEM Aluminum Die Casting Pump Body Spare Parts for American Market

Basic Info.

| Model NO. | ODM/OEM |

| Equipment | Cold Chamber Die Casting Machine |

| Software Assistance | PRO-E/Solid Work/Ug/Auto CAD/Catia |

| Surface | Trimming, Deburring,Polishing |

| Transport Package | Sea, Air, Train |

| Specification | Aluminum Alloy |

| Trademark | DCX |

| Origin | China |

| HS Code | 7217100000 |

| Production Capacity | 1000 Ton/Tons Per Month |

Product Description

OEM Aluminum Die Casting Pump Body Spare Parts For American Market

>>Technical Data Sheet:

| Process | Aluminum Die casting, Squeeze casting+T6, Zinc Alloy die casting,CNC machining, Turning |

| Equipment | Cold chamber die casting machine:200T/280T/400T/600T/800T/1100T.CNC centers, CNC turning, CNC lathes, electrical pulse, line cutting, milling, drilling, grinding |

| Material | A319, A356, A360, A369, A380, A383, A384, A413, A535, 44300, 44300, 46000, AlSi9Mg, AlSi9Cu3, ADC12, ZL102, ZL104, ZL108, Zamak2,3,5,7 ect.Squeeze Casting: A356+T6, A356.2+T6, AlSi9Mg+T6, Zl108+T6, AlTi-Alloy+T6 |

| Surface | Trimming, Deburring,Polishing, Shot blasting, Sand blasting,Tumbling, Powder coating, Anodizing, Chrome, Zinc, Electrophoresis, Passivation, Chemical coating. |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Products Application | Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect. |

>>Advantages:1.)Aluminum Lightweight Production--Squeeze Casting

We have developed the process of squeeze casting successfully. After T6 treatment, parts will be same level of strength and hardness as forging, but not need so much machining jobs, then finally realized the high strength and light weight of production.

2.)Process introduction

-Integrated the advantages of forging and die casting.-Parts forming under vacuum & high pressure conditions.-Parts are made with very high density, very strong strength & hardness after T6.-Roughness of parts are as same as the die casting.-Precision with no more machining for some complex structure

3.)Product Application>>Why Choose Us?

1. Own mould R&D team and mould making workshop.2. Own factory to offer the reasonable prices and quick response.3. Complete service from mould, production, heat treatment, surface treatment, assemble.4. 20years experience for die casting.5. Squeeze casting+T6 -- to make the parts with lightweight and strong strength.

>>Production Process:>>OEM Service:>>Our Certificate:>>Company Profile:

As a manufacturer, it is a great advantage to have our own moulds workshop, to make the perfect parts by saving time and costs. Set with full machines and skilled team, we can finish moulds very quickly for some big project with more than 50 models of parts. And changing or testing new samples always are free to customer and to be finished within short time.Full equipments support us the enough production capacity. We can make a wide range of parts from 0.01kg ~ 20kg. We can offer a very short lead time for you and adjust our production shifts according to customers urgent needs.

>>Packaging & Shipping:

>>FAQ:

Q.1:Are you a manufacturer or a trading company?

We are a 3000-square-meter factory located in shandong, China.

Q.2:How can I get a quote?Detailed drawings(PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

Q.3:Can I get a quote without drawings?Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

Q.4:Will my drawings be divulged if you benefit?No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.

Q.5: Can you provide samples before mass production?Sure, sample fee is needed, will be returned when mass production if possible.

Q.6: How about the lead time?Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

Q.7:How do you control the quality?(1)Material inspection--Check the material surface and roughly dimension(2) Production first inspection--To ensure the critical dimension in mass production(3)Sampling inspection--Check the quality before sending to the warehouse(4)Pre-shipment inspection--100% inspected by QC assistants before shipment

Q.8: What will you do if we receive poor quality parts?Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.